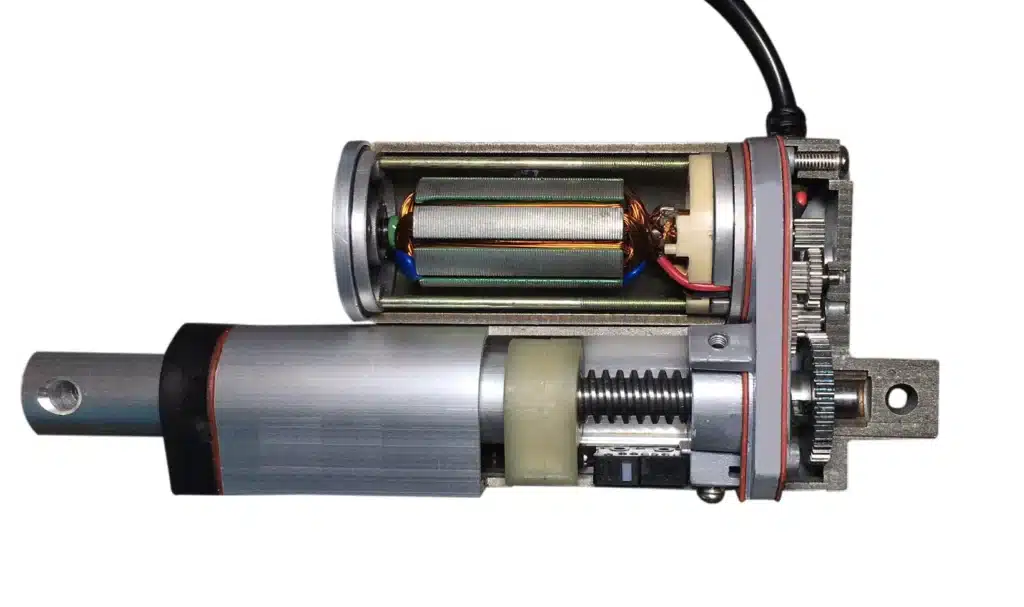

Overview:

A linear actuator is an electrical device that transfers electrical energy into mechanical energy by pulling or pushing the rod. These actuators are normally found in various mechanisms which include modern automobiles. It is important to understand how linear actuator works in order to maintain the production line and stop costly downtime.

8 Things to Remember While Programming a Linear Actuator

Avoid Over-Programming the Actuation Signal

A typical source of errors is to employ the actual signal. For example, along with the standard four-wheel actuator, there is just enough movement needed to apply half of the force to create friction or other inefficiencies at the driving wheel. Both wheels are used with similar pressure when this bug creates and cause high wear on your drive train.

Be sure that you fully understand all regular physical contacts

Normally, the contact addition which is being tested must be anticipated. When you are applying for a few statistics to identify whether the specific program is working according to expectation or not. A deep understanding of the physical geometry of the device which is under test will help decrease the number of programs which is required for the testing.

Test all Components for Wear, Corrosion, and Reliability

It is important to test all the cabling and any other electrical contacts which are connected to the actuator. This will include the known goods and those which are suspect or new in nature. In addition, you must need to know the original physical shape of the component in order to test it deeply when it is running under the load.

For Example, during the assembly process, a hook-type actuator might have surface damage from the errant screwdriver or customer tool. If you didn’t catch that damage in between the inspection process then you might face a high level of difficulty with watching these issues with the standard visual inspection program.

Document all Changes to the Program

A typical source of getting failure is leaving to return the program from testing after changing the actuation signal and load. If you didn’t change the document and return back to the testing then most probably you will lose the data for that particular part.

Your Load Must Be Sequenced Correctly During Programming:

Let’s suppose that the actuator is driven with various load sequences as compared to the plan. In this situation, this can force a particular signal onto the actuator and make damaging effects on the operation of your assembly line and production line.

The Input and Output Components are Fully Documented in Your Part Program

If you are applying a signal to the motor controller or simple motor then the expected load on the document will be placed on the controller when it is activated. If there is an unexpected load on the controller in between the operation then this can force it into an overheated state and it might cause damage. It will also happen if the controller is already loaded without expecting the input signal.

Test Your Parts Completely:

When you are programming the standard four-wheel actuator then it will be best if you understand that need to drive a motor in two various ways. You can simply go to the engine in continuous rotation or you can pulsed mode where the power is applied only when the rotating shaft moves through a particular angle. It will be best if you documented the drive time in both of these programs. The selected mode must be controlled through the braking signal on the electrical side of the device.

Ensure that Your System Can Use a Serviceable Field Device

If your system is highly used for production but there is no way to add the additional sensors or any test cells to the production line without any parts getting discharged from the line then the system is not powerful enough to get used by the field service engineers.

A non-field serviceable device must need manually reset itself after they are used and has less value to any engineer inspecting or changing the parts on the production line.

Conclusion:

Programming a linear actuator requires careful attention to various factors in order to ensure its proper functioning and prevent costly issues. Over-programming the actuation signal can lead to excessive wear and damage to the drive train.

Understanding the physical contacts and geometry of the device helps optimize testing and minimize programming requirements. Thoroughly testing all components, including cables and electrical contacts, is crucial to identify wear, corrosion, and reliability issues. Documenting any changes made to the program is essential to avoid data loss. Proper sequencing of the load during programming prevents damaging effects on the assembly and production line.

Documenting input and output components helps avoid unexpected loads that can damage the controller. Testing parts comprehensively, considering different driving modes and ensuring field serviceability of the system are key considerations for successful linear actuator programming. By following these guidelines, businesses can maintain efficient production lines and prevent downtime.

You Might Also Like: Benefits of Having High-Efficiency Furnace In Your Home